MOSH and MOAH - All about these substances

MOSH and MOAH are hydrocarbons that are considered chemical contaminants, not intentionally added to food and feed, but may be present because of processing, storage, and transportation. Among the main chemical contaminants are:

- Heavy metals

- Inhibiting substances

- Residues of past plant protection products in primary production

- Chemical migration substances from contact surfaces and packaging materials inconsistent with the food

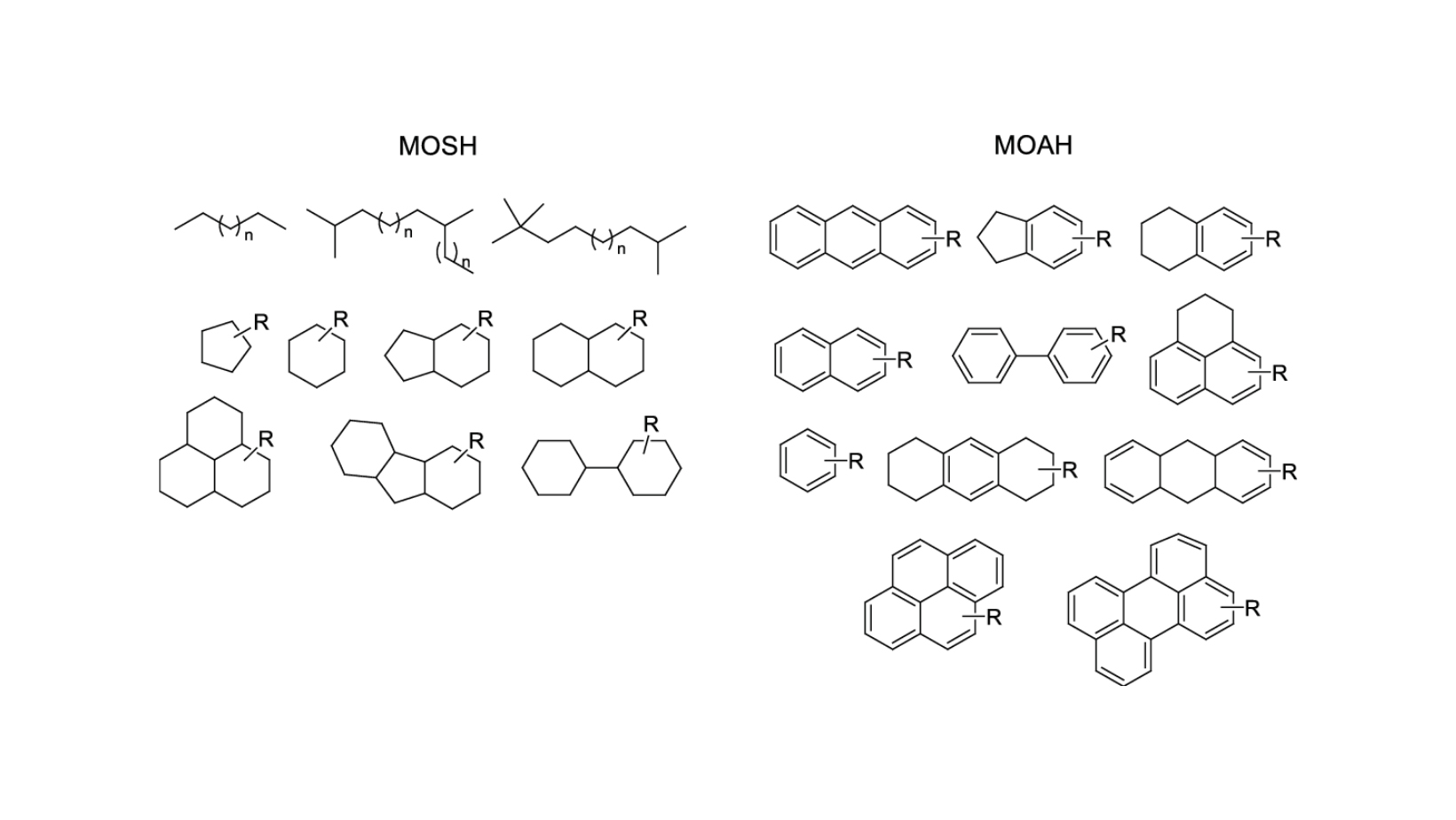

In detail, mineral oils are distinguished and classified as:

- Moah (Mineral Oil Aromatic Hydrocarbon i.e. aromatic hydrocarbons consisting of one or more benzene rings)

- Mosh (Mineral Oil Saturated Hydrocarbon i.e. branched and unbranched saturated hydrocarbons with general formula CnH2n+2)

Characteristics and risks of MOAHs and MOSHs

MOAHs are carcinogenic and genotoxic mineral oils, while MOSHs tend to accumulate in the body and damage the liver. The CONTAM (experts on contaminants within food chains) group of the EFSA (European Food Safety Authority) has assessed these health risks.

In addition, polycyclic aromatic hydrocarbons, or PAHs, which are also carcinogenic, and refined food-grade mineral oils, or MORE, may be present in MOSH and MOAH mineral oils. Still, mineral oils include saturated oligomer polymers (POSHs), used in the synthesis of plastics such as polypropylene or polyethylene, and poly alpha olefins (PAOs), the main constituents of motor or lubricant oils.

Mineral oil applications and contamination

Mineral oils are applied to printing inks and packaging materials and thus been exposed to food and products, from cardboard to recycled paper migrate to packaged food and lead to health harms.

However, mineral oil contamination can occur at any stage of the supply chain. The potential sources of contamination are very different. This is mainly due to the extensive use of mineral oil, which is present, for example, in lubricating oils used in mechanical handling equipment, in dust control agents (particularly in rapeseed and soybean processing), in burlap bags used to transport seeds and olives. This can contain up to 25 percent polyaromatic compounds, in additives used in the manufacture of plastics, and in lubricating oils found in aluminium cans used as containers.

Today, the "German Commodities Regulation" of 2011 limits MOSH and MOAH present in food to

- 0.6 mg/Kg of food (MOSH content)

- 0.15 mg/Kg of food (migration of MOAH)

If you would like more information on MOSH, MOAH and other hydrocarbons, you can contact the specialists at Settala Gas, who have always worked with these substances, placing themselves as a point of reference in the field.